Truss Webbing

Truss Webbing

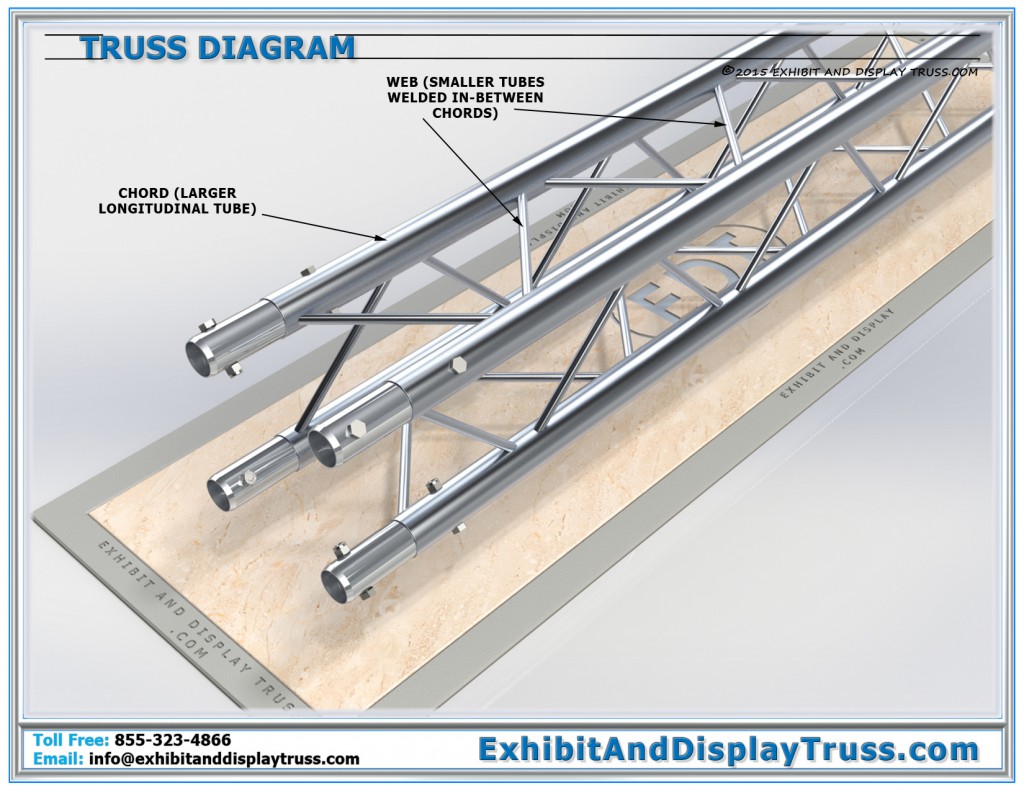

Truss Webbing refers to the smaller diameter and lengths of aluminum tube used connect the larger longitudinal tubes (truss cord) on a length of aluminum truss. The webs are welded at an angle suited to the profile size of the truss. Truss webbing provides triangulation which gives strength and durability to aluminum truss.

If you do not see angled webs for triangulation, you are not using truss, and thus strength and durability is being compromised, and instead you are using something that is masquerading as truss for its superior quality and durability. Clues that you are not using truss might be:

– Webbing is absent. No spans longer than 4 feet.

– If there is a large span, there are multiple legs to hold the span up.

– Bottom brace along the floor. Without this brace the structure would fail.

– Structure or truss is made from steel, which is difficult to manage, heavy, cheap, and will rust over time.

Truss chords are held together with webs, which are welded to each chord. Webs provide triangulation to a length of truss, and therefore strength, making aluminum truss the perfect material for building lightweight structures that are easy to transport, and very durable.